Transform Your Manufacturing with Smart Technology

Revolutionize your manufacturing operations with AI-powered automation, predictive maintenance, and IoT integration. Drive efficiency, reduce costs, and improve product quality through cutting-edge Industry 4.0 solutions.

Smart Manufacturing

AI-Powered Operations

Real-time Analytics

Data-Driven Insights

47%

Increase in operational efficiency

Industry 4.0

AI-Powered

The Future of Manufacturing is Here

Transform traditional manufacturing into intelligent, connected operations that adapt, learn, and optimize in real-time through advanced AI and IoT technologies.

Create virtual replicas of physical manufacturing processes for real-time monitoring and optimization

Key Benefits

Performance Metrics

Technology Implementation

Interactive Demo

Digital Twin Technology Simulation

Technology Stack

Automate Your Manufacturing Operations

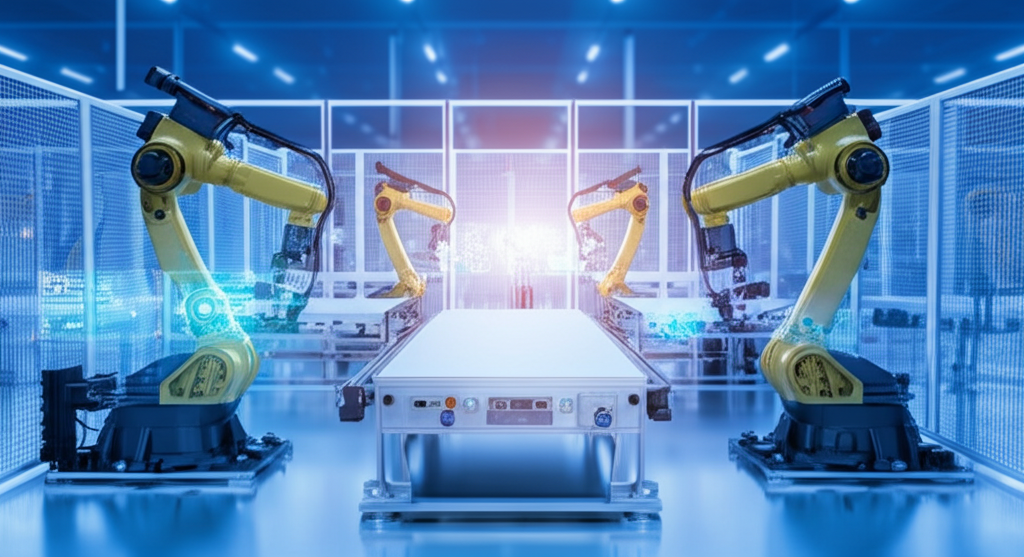

Leverage cutting-edge automation technologies to streamline operations, reduce human error, and achieve unprecedented levels of efficiency and quality in your manufacturing processes.

Robotic Process Automation

Intelligent robots that handle repetitive tasks with precision and consistency

Key Applications

Performance Impact

Automation Visualization

Robotic Process Automation

Automation reduces cycle times and eliminates bottlenecks, resulting in significant productivity gains.

Consistent, precise operations eliminate human error and ensure superior product quality.

Lower labor costs, reduced waste, and improved resource utilization drive significant savings.

Prevent Failures Before They Happen

Transform your maintenance strategy with AI-powered predictive analytics that identify potential equipment failures before they occur, reducing downtime and maintenance costs by up to 40%.

CNC Machine #1

Assembly Robot #2

Conveyor System #3

Quality Scanner #4

AI-Powered Failure Prediction

Machine learning algorithms analyze sensor data to predict equipment failures weeks in advance

Real-Time Equipment Monitoring

Continuous monitoring of equipment health through IoT sensors and advanced analytics

Maintenance Optimization

Optimize maintenance schedules and resource allocation based on actual equipment condition

Predictive Maintenance ROI

See the potential impact of implementing predictive maintenance in your facility

Optimize Your Supply Chain Operations

Transform your supply chain with AI-powered optimization that reduces costs, improves efficiency, and enhances customer satisfaction through intelligent demand forecasting and inventory management.

Connect Your Manufacturing Ecosystem

Transform your factory into a smart, connected ecosystem with IoT sensors, edge computing, and real-time analytics that provide unprecedented visibility and control over your operations.

Deploy thousands of IoT sensors to monitor equipment performance, environmental conditions, and production metrics in real-time

Key Features

Performance Metrics

Process data at the edge for instant decision-making and reduced latency in critical manufacturing processes

Key Features

Performance Metrics

Enterprise-grade security for IoT devices and data transmission, ensuring protection against cyber threats

Key Features

Performance Metrics

Sensors & Devices

Smart sensors collect real-time data from equipment and environment

Connectivity

Secure wireless networks transmit data to processing systems

Edge Computing

Local processing enables real-time decision making and response

Analytics & AI

Advanced analytics provide insights and predictive capabilities

Measurable Impact Across Operations

Our smart manufacturing solutions deliver quantifiable improvements across all aspects of your operations, from efficiency gains to cost reductions and quality enhancements.

Production Efficiency

Streamlined processes and automation

Equipment Utilization

Optimized machine usage and scheduling

Cycle Time Reduction

Faster production cycles through optimization

Overall Equipment Effectiveness

Improved OEE through predictive maintenance

Operating Costs

Reduced labor and material costs

Maintenance Costs

Predictive maintenance reduces repairs

Energy Consumption

Smart systems optimize energy usage

Inventory Costs

Optimized inventory management

Defect Rate

AI-powered quality control systems

First-Pass Yield

Improved process control and monitoring

Customer Satisfaction

Higher quality products and delivery

Compliance Score

Automated compliance monitoring

Average improvements across different manufacturing sectors

| Industry Sector | Efficiency Gain | Cost Reduction | Quality Improvement |

|---|---|---|---|

| Automotive | +52% | -38% | +45% |

| Electronics | +48% | -35% | +52% |

| Pharmaceuticals | +41% | -42% | +68% |

| Food & Beverage | +39% | -31% | +38% |

| Aerospace | +44% | -36% | +58% |

| Textiles | +37% | -29% | +35% |

Rapid Implementation

Average deployment time of 6-12 weeks

Expert Support

Dedicated team of manufacturing specialists

Proven Results

2,500+ successful implementations

Scalable Solutions

Grows with your business needs

Real-World Manufacturing Transformations

Discover how leading manufacturers have transformed their operations with our smart manufacturing solutions, achieving significant improvements in efficiency, quality, and profitability.

Global Auto Corp

Challenge

Reducing production downtime and improving quality control in a high-volume automotive assembly plant

Solution

Implemented AI-powered predictive maintenance, smart quality control systems, and real-time production optimization

Technologies Used

The transformation has been remarkable. We've not only reduced costs but also improved our product quality significantly. The predictive maintenance system alone has saved us millions in unplanned downtime.

Assessment

Comprehensive analysis of current operations

Design

Custom solution architecture and planning

Implementation

System deployment and integration

Optimization

Fine-tuning and performance optimization

Stay Ahead with Manufacturing Intelligence

Access the latest industry insights, trends, and best practices to keep your manufacturing operations at the forefront of innovation and efficiency.

Latest Insights

The Future of Smart Manufacturing: Industry 4.0 Trends for 2024

Explore the latest trends shaping the future of manufacturing, from AI-powered automation to sustainable production practices.

Predictive Maintenance ROI: A Comprehensive Analysis

Deep dive into the financial benefits of predictive maintenance, with real-world case studies and ROI calculations.

Supply Chain Resilience in the Digital Age

How digital technologies are helping manufacturers build more resilient and agile supply chains.

Smart Manufacturing Summit 2024

AI in Manufacturing Webinar

Industry 4.0 Workshop

The Complete Guide to Smart Manufacturing Implementation

A comprehensive 50-page guide covering everything from planning to execution

Predictive Maintenance Best Practices

Industry best practices and implementation strategies for predictive maintenance

IoT Security in Manufacturing

Essential security considerations for IoT implementations in manufacturing

Stay Updated

Get the latest manufacturing insights delivered to your inbox weekly.

Start Your Smart Manufacturing Journey Today

Join 2,500+ manufacturers who have transformed their operations with our AI-powered solutions. Get started with a free consultation and discover your potential for improvement.

Schedule a Consultation

Get personalized recommendations for your manufacturing operations

Request a Demo

See our smart manufacturing solutions in action

Download Resources

Access our comprehensive manufacturing transformation guide

Need Immediate Support?

Our manufacturing experts are available 24/7 for urgent consultations

Join industry leaders who trust ESG for their manufacturing transformation